Differences and similarities

In order to understand the differences and similarities between Tailoring and Bespoke Dressing, we must first understand the meaning of each.

From the Arabic al-hayatt or “he who sews”, the word tailor leads directly to tailoring or the art of sewing cloths to cover the body. The pursuit of perfection is the craft’s mission, which has led to other specialisations contributing to this desire. The cutter who can specialise in different models, the seamstress who has to be skilful and sensitive to the tension of the thread according to the fabric she is sewing, the officers who assist the tailor in taking measurements or the seamstresses in opening seams and finishing each operation, and the tailor or fashion designer himself, the master or mistress, who measures and assesses the client, scratches out his or her desire with painterly art and sculpts a bust with a hot iron, moulding it between mane weaves until the soul of the creator influences the fabric and it covers the client’s body with elegance and rigour.

The growing need to serve a greater number of people and in order to make the product more accessible, the industrialisation and mechanisation of some operations brought greater speed and lower production costs and, as a result of exhaustive anatomical studies and technological development, a certain set of parameters was reached that allowed the advent and success of the standardised clothing industry, better known as ready-to-wear.

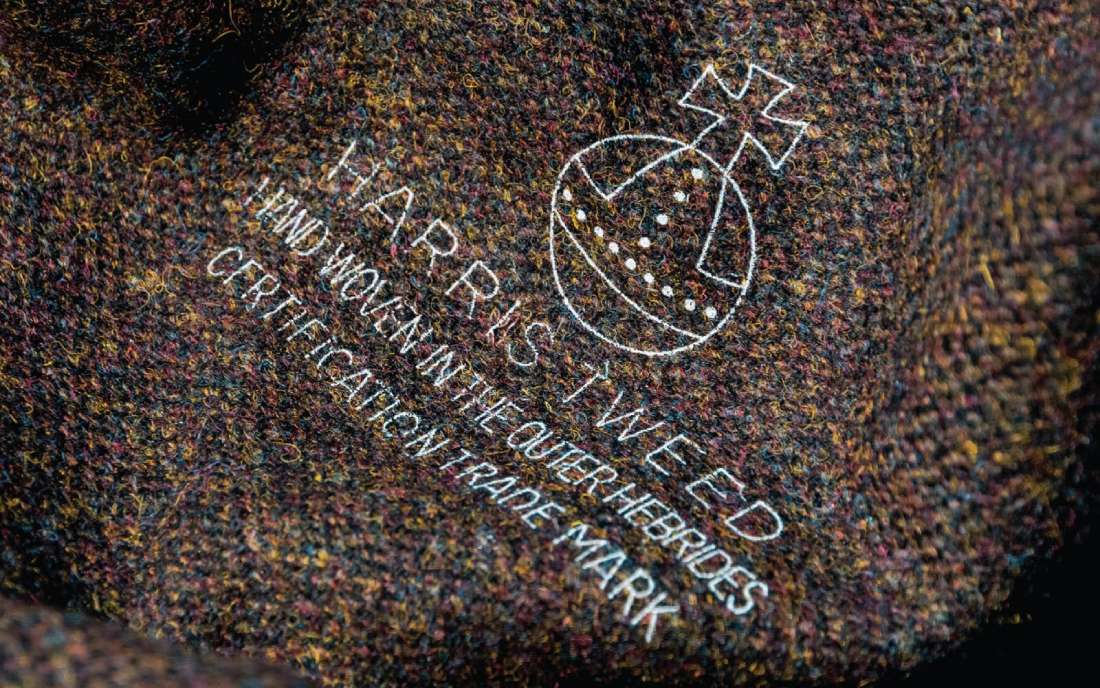

While the art of tailoring maintains centuries-old processes so that tradition and know-how are not lost, the knowledge and technology applied in the industry has led it to evolve to new levels of perfection and to the creation of new professions, such as dressmaker or fashion designer, as well as elevating other industries such as lining, buttons and other types of trims. The traditional tailor was therefore a craftsman capable of all kinds of cuts, who offered knowledge to the industry and which it took up, evolving until the concept of “made-to-measure dressing” was reached, which also created a new professional, the made-to-measure stylist, on whom all the information to be processed by tailoring will depend.

In traditional tailoring, the tailor cuts each pattern from scratch, based on the client’s measurements and request, and should, in principle, give the work his personal style, as if it were his signature. For example, there are tailors who only work with a beak band on jackets and blazers, because that’s their signature. A good tailor makes a point of hand-finishing and, above all, perfects his work to the customer’s satisfaction.

Time and the relationship with the customer are fundamental and must influence the final price, which the connoisseur understands and applauds. The more sophisticated, appreciative customer with equal purchasing power will also seek out your shoemaker, your shirtmaker or your engraver and thus obtain your bespoke wardrobe.

For its part, bespoke tailoring, thanks to know-how combined with new technologies, has evolved to extremely high levels of quality when partnerships are made between the best, and can compete on performance and price levels as well as surpassing traditional craftsmanship in terms of service. The stylist who interacts with the client is the interpreter of the client’s wishes and the proponent of the best solutions.

He is also the sculptor of the improvements. After taking the client’s measurements, the first fitting is done on the spot under a base mould that best suits the client’s comfort. Under this base mould, it’s up to the stylist to read the dozens of parameters that can be altered so that the garment fits perfectly. The variety of models and fittings, the wide range of finishing options, whether manual or not, and decorations, open up a range of imagination that the creativity of both will make into a dream garment.

Made-to-measure stylists and brands specialising in this service, such as suMisura Mestres de Medida Lisboa, have established partnerships with other areas of clothing, making it possible for customers not only to have their executive or ceremonial suit, casual blazer or chino trousers made, but also to have all their shirt, tie, knitwear and shoe work made to measure.

We can therefore conclude that customers who, for various reasons, cannot find the solutions they are looking for in ready-to-wear clothing, whether in terms of the necessary measurements or, above all, the free choice of models, patterns and colours, will find in classic craftsmen the right source for an exclusive and genuine piece of work, you now have the option of customised clothing or footwear for a world of solutions, from the everyday suit or blazer to the goodyear or casual shoe, from the industrially made tie to the sophistication of the 5 and 7-pleat tie, a similar or sometimes even more comprehensive offer at a somewhat more competitive price.

The elegant world of bespoke clothing is not at all about compulsive buying and requires a little time and dedication to the important act of choosing and purchasing. It is therefore recommended that the customer pay attention not only to their needs but also to the time required to construct and make their garments, which on average can take between 3 and 4 weeks, depending on the work. Giving time to the tailor means taking care of yourself as you would a trip to the spa, the gym, a must-attend conference, a holiday or a meeting with friends. Appointments reserve that exclusive time and concentrated attention that every man or woman’s style deserves, and being seen by a passionate professional tailor or a good tailor is far more rewarding than being seen by a solicitous clerk.

In conclusion, if the option is to dress well with judgement and style, the customer will find satisfactory solutions both in tailoring and in the offer of a made-to-measure service, because both offer an inter-relationship with the customer and provide that sublime feeling of having an exclusive, 100% dedicated, high-quality garment. If time is still money and good taste persists, perhaps that’s where the biggest difference lies between traditional and technological tailoring. The difference will always be in the people and the professional you choose and can afford.